Key Highlights:

- Chinese scientists built flexible semiconductor chips inside fibres as thin as human hair.

- Each fibre packs up to 100,000 transistors per centimetre while staying stretchable.

- The chips survive bending, washing, heat, and heavy pressure.

- The breakthrough could power smart clothing, brain interfaces, and VR wearables.

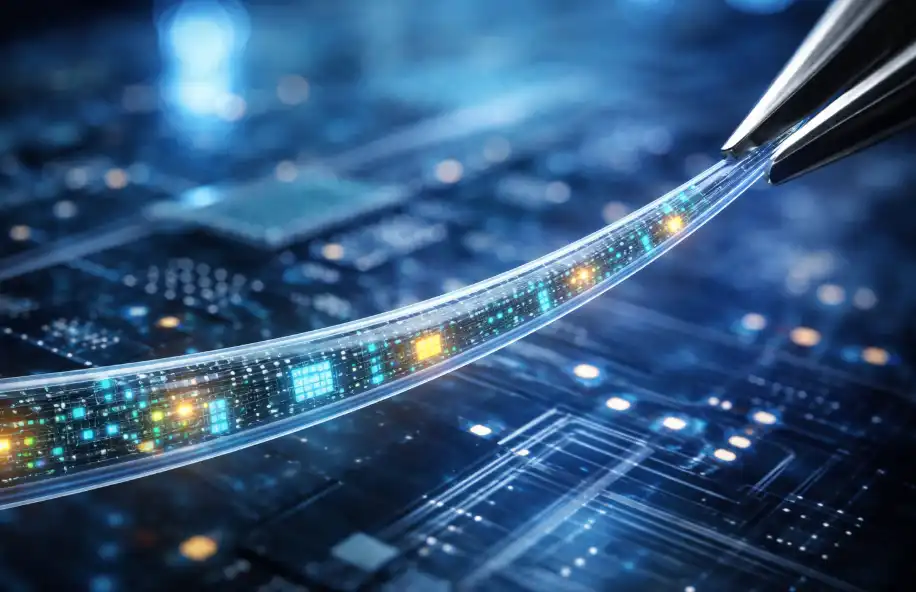

Chinese scientists have created a hair-thin semiconductor chip that works like a computer while staying fully flexible. Built inside a fibre, the device packs dense circuits into threadlike strands that can bend, stretch, and survive washing. The breakthrough could turn ordinary fabric into computing surfaces, reshaping wearables, healthcare, and human–machine interfaces.

The work, published in Nature, comes from a team led by Peng Huisheng at Fudan University in Shanghai. The researchers developed what they call a fibre integrated circuit (FIC). Instead of building chips on rigid wafers, they fabricated circuits on elastic material and rolled them into a scroll-like fibre.

Despite being as thin as human hair, each fibre reaches a transistor density of 100,000 per centimetre. That matches industry standards used in conventional chip integration.

How Does a Fibre Become a Chip?

Traditional chips rely on flat silicon surfaces. The FIC flips this model. Engineers first pattern a complete circuit on a stretchable base. They then roll it into a cylindrical strand, embedding resistors, capacitors, diodes, and transistors into one continuous fibre.

At current lab precision, a 1mm fibre can host tens of thousands of transistors. Extend that fibre to a metre, and the count rises toward a million. According to the team, future nanometre-scale photolithography could push integration even higher.

The fibre itself acts as a microcomputer. It processes both digital and analogue signals. It also supports neural-style computing, matching the performance of advanced in-memory image processors.

Why This Semiconductor Breakthrough Matters

The fibre chips endure conditions that rigid electronics cannot. Tests showed:

- 10,000 bending and abrasion cycles

- Stretching up to 30 percent

- Twisting at 180 degrees per centimetre

- Over 100 wash cycles

- Heat up to 100°C

- Compression under a 15.6-tonne truck

Based on this, the team integrated power, sensing, computing, and display into a single fibre. No external chips. No bulky wires.

This enables machine-washable smart clothing. Sleeves could show navigation. Sportswear could display live health data. Gloves could simulate touch in virtual reality. In medicine, hair-thin fibres could sense, process, and stimulate brain signals while matching the softness of neural tissue.

What Comes Next?

The researchers report early success in scalable lab manufacturing. That suggests a path toward mass production.

If adopted widely, this semiconductor approach could shift electronics away from rigid boards and into everyday materials. Fabric would no longer just cover the body. It would compute, sense, and respond.

In the long run, hair-thin semiconductor fibres could redefine how humans interact with machines—quietly woven into what we wear.